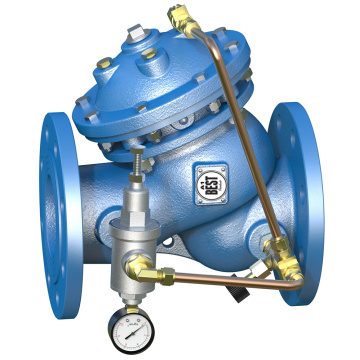

Non-Slam Check Valve DN65

| Payment Type: | L/C,T/T,D/P,Paypal |

|---|---|

| Terms of Trade: | FOB,CIF |

| Delivery Time: | 15 Days |

| Productivity: | 100Kpcs per month |

|---|---|

| Brand: | A1BEST |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Taiwan |

| Supply Ability: | Depend on The Quantity |

| Certificate: | API Ce ISO Ts |

| HS Code: | 8481804090 |

| Port: | Shanghai,Kaohsiung |

Basic Info

Model No.: NSCV08

Click on the follow link to find out more information: https://www.aone-best.com/y-type-non-slam-check-valve/

Company Info

- Company Name: A1BEST International Corporation

- Representative: CHANG YUAN CHIEH

- Product/Service: VALVES , BUTTERFLY VALVE , GLOBE VALVE , FLAT VALVE , STATION VALVE , HYDRAULIC CONTROL VALVE

- Capital (Million US $): US $ 25,000,000

- Year Established: 2017

- Total Annual Sales Volume (Million US $): US$50 Million - US$100 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): US$50 Million - US$100 Million

- No. of Production Lines: Above 20

- No. of R&D Staff: 21 -30 People

- No. of QC Staff: 31 -40 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: Suzhou, Jiangsu Province, China

- Contact Person: Mr. Jason Chang

- Tel: +886-912-195558

Premium Related Products

Hot Products

forged precision brass thread knurling cap nutsNut, Single Ferrule, 1/4 In Tube Sz, BrassForged Male Threaded Brass Compression Fitting Straight Reducing Coupler15mm 22mm 25mm 28mm 40mm 50mm Dimensions Lever Handle 2 Way Npt Female Threaded Brass Ball Valve5 way brass fittingLow price promotional brass water float valvesTop level hot-sale 200 wog brass manual gate valve4 Way Brass FittingDesigner Professional Pipe Male Female Brass Insert Union3/4 Forged Brass Female Gas Ball Valve With Steel Lever HandleJD-1002 Brass Male Fittings With Hose BarbJD-5511 Brass Ball ValveFemale Threaded Brass Water Spring Vertical Type Check Valve ForgedBrass Forged Equal Tee Compression Fittings For PEX-AL-PEX PipeHigh qulity and low price zhejiang manufacture forged original brass color male threaded npt brass nipple tube fittingsNickel Plated Male Elbow Brass Press Fittings For PEX-AL-PEX Pipe